Free cooling with water

Free cooling with water is an economic and environmentally friendly alternative to producing cold. In fact, many countries around the world have installed free cooling to protect their data centers with fantastic results.

When utilizing free cooling as your chosen source, less mechanical cooling is required. That means fewer harmful refrigerants and fossil fuels are necessary to keep systems running.

Thanks to our continuous research and development strategy, we can supply products for any cooling application, regardless of cooling media or source. In other words, we can utilize any kind of aggressive cooling media you want to use. This covers everything from sea and brackish water, to river and well water.

Plus, with a plate heat exchanger in your system, you can isolate the chilled water loop from all your sensitive equipment. So, you can confidently eliminate any potential for corrosion, scaling or constant maintenance.

Adding a heat exchanger to a free cooling system will also require less space, so it is an extremely compact solution. Please note that in sea and freshwater applications, we recommend you use a filter to protect your heat exchanger.

With that said, we at Alfa Laval have so much more to offer than outstanding products. We are always available to use our leading expertise and provide quality solutions to any of your production needs.

Free cooling with a chiller

In the spring and autumn, a combination of free cooling and chiller-produced cold is used, whereas in summer, the chiller does most of the cooling alone. Water is a form of free cooling and can come from rivers, lakes, (deep) oceans, ground water, ice and snow storage.

Free cooling with a chiller bypass

Producing electricity often involves air pollution, so reducing the electricity consumption of your chiller has a positive effect on the environment. Installing a chiller bypass system will save costs and improve the PUE and CUE value of your system. Plus, it will help cover cooling requirements during periods when the free cooling source has lower temperatures than your chilled water, like winter.

Savings across many dimensions

Using free cooling with water and a well-designed gasketed plate heat exchanger improves the cost-efficiency and sustainability of your data center in many ways. We know this because using AHRI performance certified heat exchangers has been proved to reduce your power usage effectiveness (PUE) by 2 %. It will even decrease the carbon usage effectiveness (CUE) of your facility by the same amount. Plus, a heat exchanger in your cooling system enables more efficient heat recovery and lower OPEX as a result.

Design your system for maximum profitability

Designing heat exchangers for a datacenter is different to designing for HVAC-applications. Firstly, we need to find the right temperatures for a continuous cooling process. Then there are other important design parameters to consider and calculate, like flow rates, turbulence, fouling, and pressure drop.

A heat exchanger that is designed correctly will increase cooling system reliability and maintain high efficiency levels. At Alfa Laval we can help you optimize your cooling needs with our proven heat exchanger solutions and leading expertise in datacenter cooling.

Watch this video with our expert, Gemma Reeves, to learn more about how to design heat exchangers for free cooling with water in a datacenter.

The benefits of a gasketed plate-and-frame heat exchanger

- Enables bypassing of chiller for free cooling when outdoor temperature and climate allows

- Reduced use of water and pumping costs thanks to cleaner pipes and minimized flushing needs

- Reduced maintenance costs for downstream cooling equipment

- Improved uptime with no unplanned shutdown due to corrosion issues

- Simple and easy cleaning of heat exchanger by single operator in just a few hours

- Certified performance in accordance with AHRI regulations

Cooling loop protection

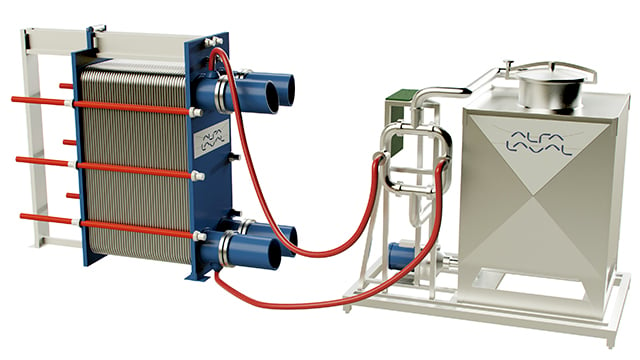

A cooling system that incorporates a heat exchanger and an Alfa Laval Filter can be used to cool the most sensitive process equipment, even with polluted or corrosive water. The Alfa Laval Filter (ALF) is integral to any heat exchanger cooling system, as it removes debris that can foul and clog heat exchangers.

Without the Alfa Laval Filter, mussels, seaweed, and other forms of marine life can settle on the heat transfer surfaces, even after effective screening at the water intake stage. The growth conditions in the cooling system are ideal for these lifeforms, which increases their multiplication rate and causes less effective heat transfer. In many cases they can even cause heat exchangers and other equipment to breakdown.

Watch this movie to learn more about the ALF solution.

The benefits of an ALF filter

- Heat exchangers are protected from debris and marine life

- Increased cooling system uptime

- Lower maintenance costs

- Ensures continuous GPHE performance, even when backflushing

- Backflushing is performed automatically without interrupting the filtering process

- Easy installation and maintenance

- Proven & reliable technology

- Full support from Alfa Laval Service teams throughout equipment lifecycle

Discover the future of green IT with Alfa Laval

Alfa Laval has supplied solutions for cooling server rooms since the earliest days of the internet. Today, we offer a wide range of solutions for data center cooling, all backed by a worldwide service network with experts who understand your business. By partnering with us as you begin planning your data center project, we can help you design a system that ensures you get maximum cooling efficiency and reliability.

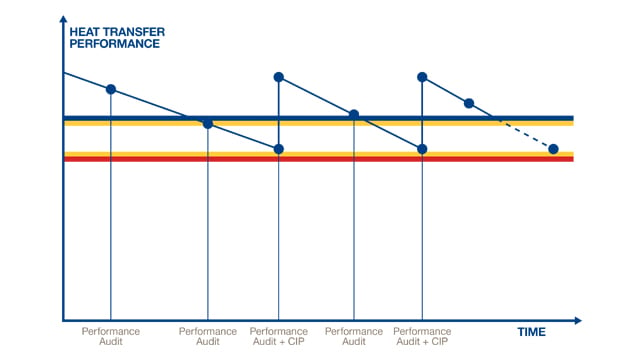

Performance audits

Our trained experts review and analyse the actual thermal performance of your equipment. Using modern tools, they can detect for fouling or similar risks, enabling you to better plan your maintenance needs in order to optimize system uptime.

Cleaning-in-place

Alfa Laval cleaning-in-place (CIP) systems enable quick and easy in-line cleaning of heat exchangers for managing fouling. With environmentally friendly, biodegradable cleaning agents, our CIP eliminates unnecessary repeated opening of your equipment. As a result, you drastically reduce spare parts consumption and the man-hours needed for maintenance.

Backflushing

Alfa Laval recommends frequent backflushing on the incoming flow of cooling water for short periods of time. In this sequence, the reversed water scrapes off and flushes out accumulated debris from the heat exchanger plate surface. Using backflush equipment saves time and money while minimizing downtime.

Ready to learn more?

Want to find out how we can boost the cost efficiency and sustainability of your data center with smart cooling tower solutions based on leading plate heat exchanger technologies? Contact us today, and our experts will be in touch!